Ididit Collapsible Steering Columns

Safer Steering Columns

Steering-components company Ididit has updated its lineup of collapsible steering columns, and they are now safer than ever.

The inner-workings now feature shift-tube improvements and additional perforations for double the amount of column collapsibility over previous models. Ididit also used Delrin shear pins for improved resistance to fatigue and wear. Delrin, is a thermoplastic polymer called acetal plastic that is manufactured by the polymerization of formaldehyde, and it is often used in bushings and other components.

For drivers of custom cars and racers, it simply means a safer steering column in case of an accident.

“Ididit is constantly researching ways to improve our products,” according to Peter Hathaway, company engineer. “The recent upgrades to our collapsible columns mean greater peace of mind for hot rodders and racers should they ever experience a front-end impact.”

Hathaway explains that rigorous testing of sample shafts showed the Delrin pins provided dimensional stability, high toughness and fatigue resistance across a wide temperature range, and withstood exposure to solvents, water, oils and other petroleum products.

After researching, developing and building prototypes using Delrin pins to replace the steel “roll-pin” style shear pin being used in ididit collapsible columns, the engineering team sent the newly-designed columns to third-party testing company Elements to be evaluated for collapsibility under compression in a displacement versus load scenario.

After testing, the shafts built with Delrin pins showed no discernible loss due to fatigue cycling, and the shafts built with double Delrin pins were ultimately selected to replace the current design, as the peak loads required for collapse were deemed safe while still maintaining structural integrity and robustness to withstand the rigors of shipping and installation.

After completing testing, ididit’s engineering team conducted an impact test simulating the testing standards used by the United States (and many other countries around the world). A 75-pound weight was dropped from a height of 15 feet to simulate a torso impacting the steering wheel at 15 miles-per-hour. After implementing a new double-tube shaft design featuring additional perforations, the column collapsed over 7 inches, a significant difference that increases driver safety, both on the track and on the street.

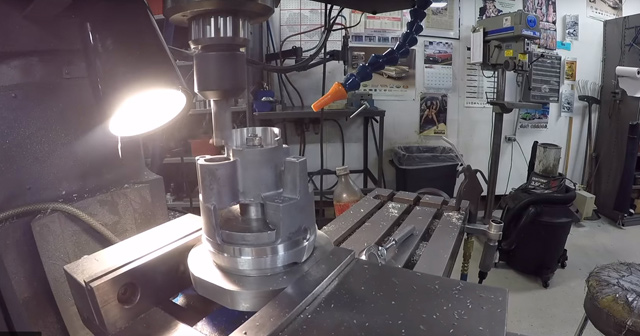

Here are the videos from ididit’s own tests of the collapsible columns:

Test #1: Collapsible Column Without Double Shaft Tube

Test #2: Collapsible With New Double Shaft Tube

“We’re excited to immediately offer this upgraded design on our complete line of retrofit collapsible columns, including the Pro-Lite line, as well as tilt shift and floor shift models,” Hathaway added. “Any vehicle that came with a collapsible column from the factory—we build a collapsible column for that application, and now one that’s safer than ever.”

All ididit collapsible columns are now manufactured with Delrin pins and they utilize the new double-shaft design.

COMPANY DETAILS |

|

|

Company |

Ididit |

|

Website |

|

|

Connect |

|

|

|

|

|

Phone |

(517) 424-0577 |

|

Address |

610 S. Maumee St. |

|

Tecumseh, MI 49286 |

ABOUT Ididit®

Born out of the American entrepreneurial spirit, ididit emerged out of a small garage in 1986 and has grown into the leading aftermarket steering-column manufacturer you see today. Ididit has been making the finest quality steering columns and related accessories for the hot-rod and muscle-car enthusiast for the past 30 years and continues to expand on that tradition. Located in Tecumseh, MI, ididit manufactures top-quality, American-made steering columns for the automotive aftermarket, as well as steering systems for industrial, commercial and government vehicles. Ididit also produces specialty columns for a multitude of applications such as golf carts, ATV/UTV, tow vehicles and driving simulators.